Features

◇ Suitable for handling flat objects.

◇ Various materials for different workpieces. Conductive silicone can effectively prevent static damage to electronic products.

Fluorine rubber material has good corrosion resistance, which can effectively reduce the mark left on workpiece after mark free treatment.

◇ Various sizes are available with workpiece with different sizes.

Applications

◇ Smooth wooden plate

◇ Smooth steel plate

◇ Plywood

◇ Plastic plate

◇ Electronic component

| How to order | ||||||||

| SF 50 N -G2F -EB ① ② ③ ④ ⑤ | ||||||||

| ① Series | ② Diameter | ③ Material & Hardness | ④ Connection thread | ⑤ Cone valve | ||||

| SF | 15 - φ15mm 20 - φ20mm 25 - φ25mm 30 - φ30mm 40 - φ40mm 50 - φ50mm | 75 - φ75mm 110 - φ110mm 150 - φ150mm 200 - φ200mm 300 - φ300mm | N - NBR★ S - Silicone★ WS - White silicone CS - Conductive silicone | Nil - Suction cup alone M5M- M5 Male thread GIF - Gl/8 Female thread G1M- Gl/8 Male thread G2F - Gl/4 Female thread G2M - Gl/4 Male thread G3F - G3/8 Female thread G3M - G3/8 Male thread G4F - Gl/2 Female thread G6F - G3/4 Female thread | Nil - Without cone valve EB - With cone valve | |||

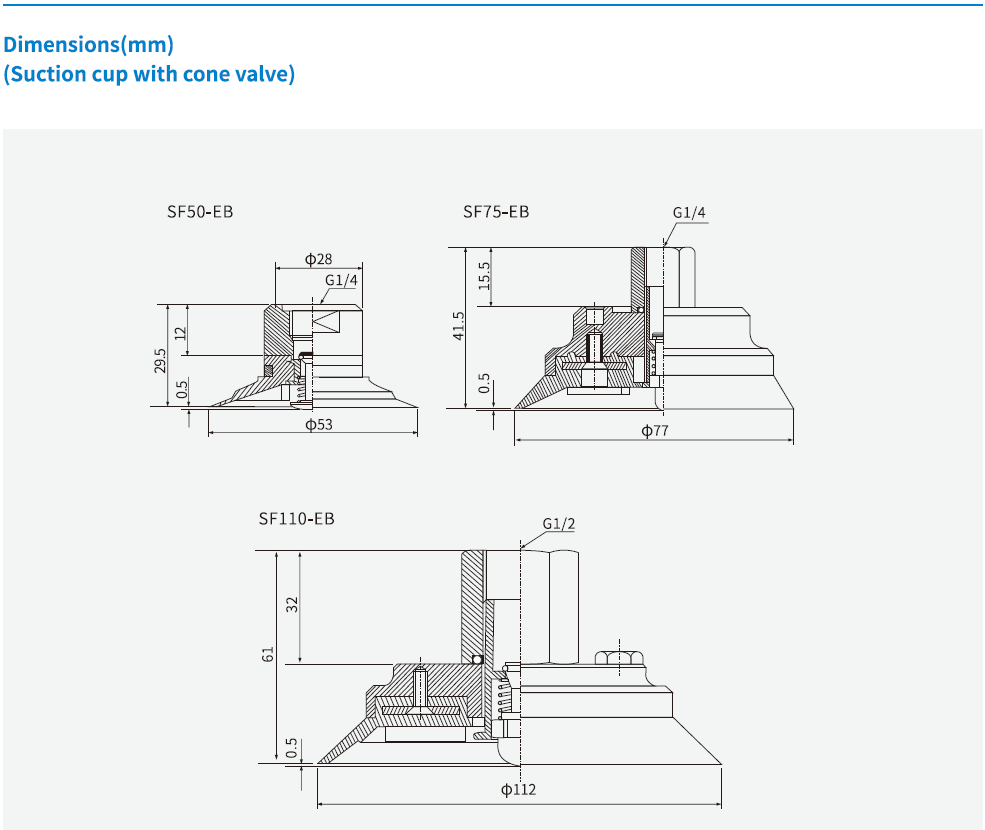

◇Note: "★" - common material, in stock. For other materials, please consult with AIRBEST. Cone valve suits suction cup SF50-150.

| Selection | |||||||||

| Connection thread | M5M | G1F | G1M | G2M | G3F | G3M | G4F | G6F | EB |

| SF15 | - | ● | ● | - | - | - | - | - | - |

| SF20 - 30 | - | ● | ● | - | - | - | - | - | ○ |

| SF40 | - | - | - | - | - | - | - | - | - |

| SF50 | - | - | - | ● | ● | ● | - | - | - |

| SF75 | - | - | - | ● | - | - | - | - | ○ |

| SF110 - 200 | - | - | - | - | - | - | ● | - | - |

| SF300 | ● | - | - | - | - | - | - | ● | - |

◇Note: "●"- standard, in stock. "○"-selective,no stock."—"-unavailable.

| Technical parameters | |||

| Model | Pull-out force (N) | Inner volume (cm³) | Recommended hose dia. (mm) |

| SF15 | 8 | 1 | 6 |

| SF20 | 15 | 1 | 6 |

| SF25 | 22 | 1 | 6 |

| SF30 | 32 | 2 | 6 |

| SF40 | 60 | 3 | 6 |

| SF50 | 88 | 7 | 6 |

| SF75 | 200 | 20 | 8 |

| SF110 | 430 | 60 | 10 |

| SF150 | 795 | 160 | 10 |

| SF200 | 1,500 | 550 | 12 |

| SF300 | 3,200 | 730 | 12 |

◇Note: Testing vacuum level -60kPa.Workpiece with smooth and clean surface. The data of pull-out force as

above are figured out without considering safety factor. The data may be different according to different

workpiece surfaces.

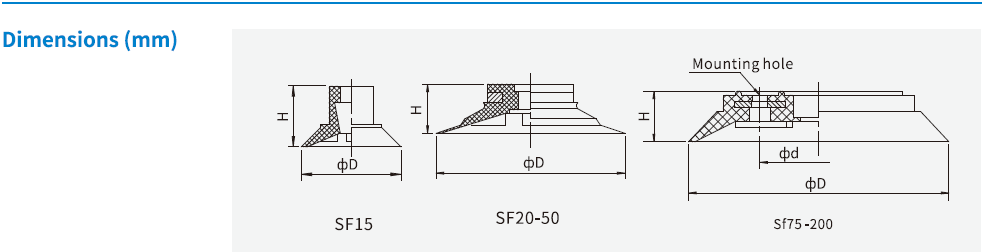

| Model/ Size | D | H |

| SF15 | 16.5 | 11 |

| SF20 | 22 | 8 |

| SF25 | 27 | 9 |

| SF30 | 32 | 10 |

| SF40 | 42 | 13 |

| SF50 | 53 | 17.5 |

| Model/ Size | D | H | d | Mounting hole |

| SF75 | 77 | 13 | 35 | 4-φ6.5 |

| SF110 | 112 | 20 | 55 | 8-φ6 |

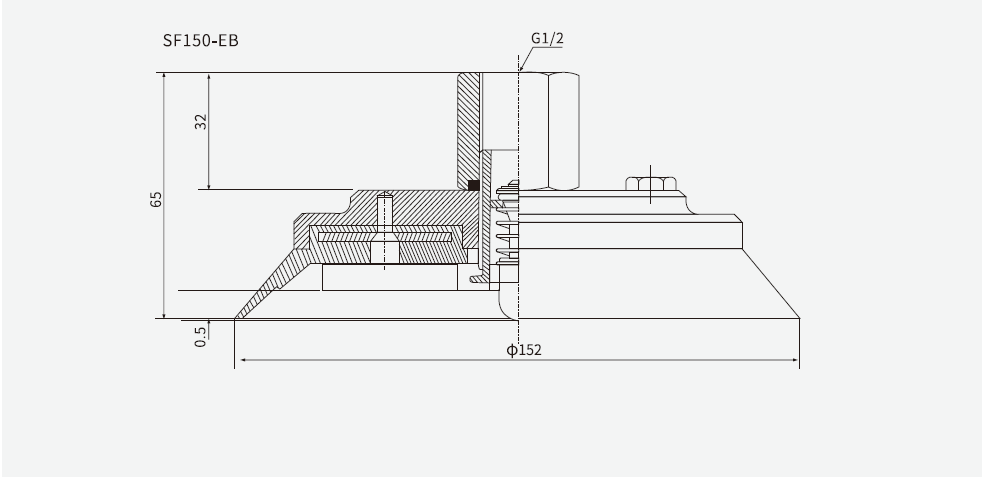

| SF150 | 152 | 26 | 70 | 8-φ6 |

| SF200 | 200 | 45 | 40 | 4-φ9 |

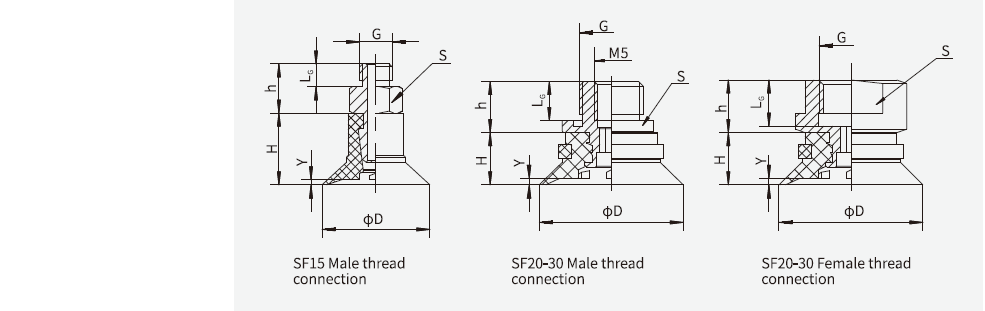

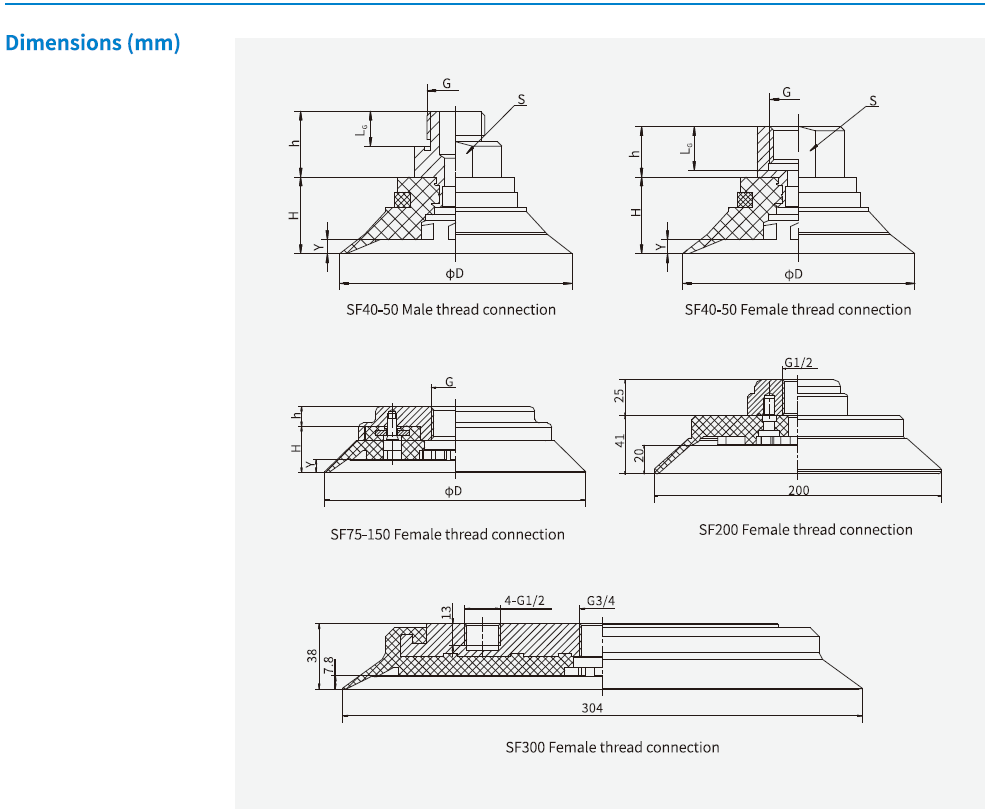

| Model/Size | D | H | G | LG | h | S | Y |

| SF15-M5M | 16.5 | 11 | M5 | 3.5 | 7.5 | 7 | 0.8 |

| SF20-G1F | 22 | 8 | G1/8 | 7 | 8 | 13 | 1 |

| SF20-G1M | 22 | 8 | G1/8 | 6 | 7.8 | 13 | 1 |

| SF25-G1F | 27 | 9 | G1/8 | 7 | 8 | 13 | 1 |

| SF25-G1M | 27 | 9 | G1/8 | 6 | 7.8 | 13 | 1 |

| SF30-G1F | 32 | 10 | G1/8 | 7 | 8 | 13 | 1.2 |

| SF30-G1M | 32 | 10 | G1/8 | 6 | 7.8 | 13 | 1.2 |

| SF40-G1F | 42 | 13 | G1/8 | 7 | 10 | 17 | 1.2 |

| SF40-G1M | 42 | 13 | G1/8 | 6 | 12 | 17 | 1.2 |

| SF50-G1F | 53 | 17.5 | G1/4 | 10 | 13 | 24 | 3.2 |

| SF50-G2M | 53 | 17.5 | G1/4 | 9 | 17 | 24 | 3.2 |

| SF50-G3F | 53 | 17.5 | G3/8 | 10 | 13 | 24 | 3.2 |

| SF50-G3M | 53 | 17.5 | G3/8 | 10 | 18 | 24 | 3.2 |

| SF75-G2F | 77 | 13 | G1/4 | - | 13 | - | 4 |

| SF110-G4F | 112 | 20 | G1/2 | - | 9 | - | 6 |

| SF150-G4F | 152 | 26 | G1/2 | - | 10 | - | 8 |

| Mounting parts | ||||||||

| Item | Model | Applicable suction cup | ||||||

| F - Female thread | M - Male thread | |||||||

| Fitting for suction cup | - | PJS-M5M-SC3 | SF150 | |||||

| PJS-G1F-SF1 | PJS-G1M-SF1 | SF20、25、30 | ||||||

| PJS-G1F-SF2 | PJS-G1M-SF2 | SF40 | ||||||

| PJS-G2F-SF3 | PJS-G2M-SF3 | SF50 | ||||||

| PJS-G3F-SF3 | PJS-G3F-SF3 | SF50 | ||||||

| PJS-G2F-SF4 | - | SF75 | ||||||

| PJS-G4F-SF5 | - | SF110 | ||||||

| PJS-G4F-SF6 | - | SF150 | ||||||

| PJS-G4F-SF7 | - | SF200 | ||||||