Features

◇ Suitable for very rough and uneven surface and all other applications in which traditional suction cups can't be used.

◇ NF(black) is suitable for handling workpiece with rough surface and for outdoor use. Good weather and ozone aging

resistance, but poor in yield elasticity and storage stability. It is not suitable for food industry.

◇ OF(orange) is suitable for handling workpiece with a very rough surface. It has good yield elasticity, wear resistance,

tear resistance, high cut resistance and good malleability, but poor in oil resistance, heat resistance and aging resistance.It is not suitable for food industry.

◇ Various sizes suitable for workpiece of different sizes.

Applications

◇ Buckle plate

◇ Tile

◇ Marble

◇ Cement board

◇ Grid metal plat

Usage

◇ The sponge lip can compensate the gap on the rough surface, which can be used in the occasion that the general suction

cup cannot sucks the workpiece firmly. However, more attention needs to be paid while using due to its poor tear resistance.

The sponge lip only has the sealing function and cannot handle the pulling condition. Hence, firstly be sure to press the flat

rectangular foam rubber pad and the workpiece to the limit, and then open the vacuum to pick up the workpiece. When

releasing the workpiece, firstly place it in the specified position, then stop vacuum in order to protect the sponge lip from

tearing. Please consult with customer service if any thing unclear in actual operation.

| How to order | ||||

| SOP 40 NF -G2F ① ② ③ ④ | ||||

| ① Series | ② Diameter | ③ Material& Hardness | ④ Connection thread | |

| SOP | 40 -φ40mm 64 -φ64mm 92 -φ92mm | 127 -φ127mm 180 -φ180mm 220 -φ220mm | NF - Neoprene foam rubber OF - Geranium foam rubber | G2F - G1/4Female thread G3F - G3/8Female thread G4F - G1/2Female thread |

| Selection | |||

| Model | G2F | G3F | G4F |

| SOP40 | ● | - | - |

| SOP64 | ● | - | - |

| SOP92 | - | ● | - |

| SOP127 | - | - | ● |

| SOP180 | - | - | ● |

| SOP220 | - | - | ● |

◇Note: "●"- standard, in stock. "—"-unavailable.

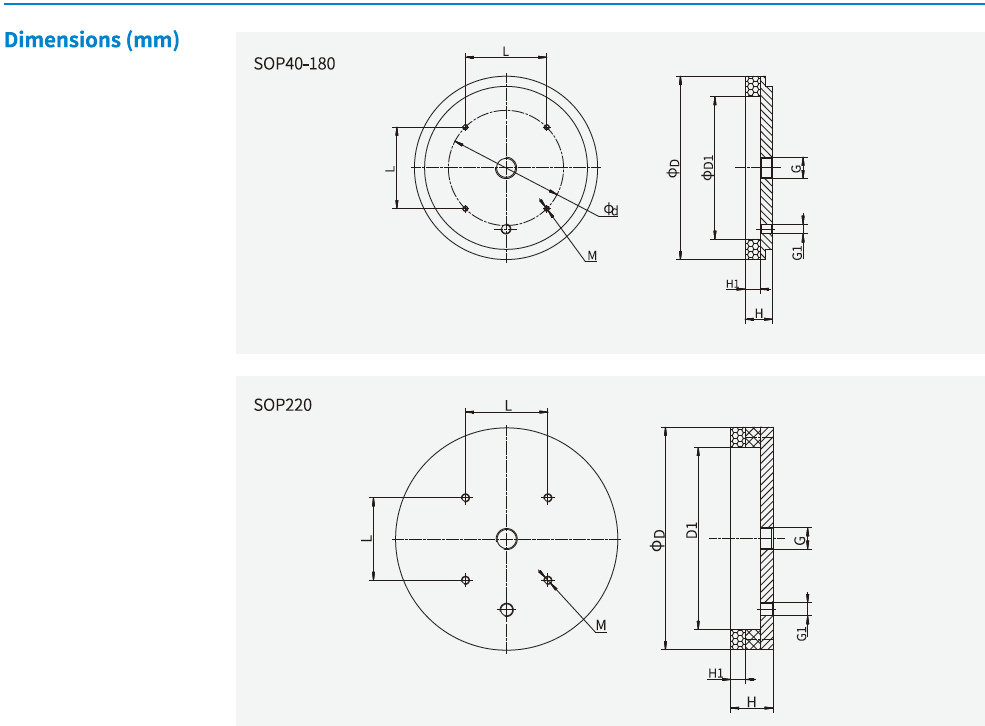

| Model/Size | Pull—out force (N) | D | D1 | H | H1 | G1 | L | M | d | G |

| SOP40 | 7.8 | 40.0 | 20.0 | 25.0 | 15.0 | - | - | - | - | G1/4 |

| SOP64 | 35.0 | 64.0 | 40.0 | 25.0 | 15.0 | - | - | 4-M5 | 40 | G1/4 |

| SOP92 | 85.0 | 92.0 | 64.0 | 26.0 | 15.0 | - | - | 4-M5 | 70 | G3/8 |

| SOP127 | 175.0 | 127.0 | 92.0 | 30.0 | 15.0 | G1/8 | 70 | 4-M5 | - | G1/2 |

| SOP180 | 385.0 | 180.0 | 127.0 | 27.0 | 15.0 | G1/8 | 80 | 4-M8 | - | G1/2 |

| SOP220 | 635.0 | 220.0 | 180.0 | 42.0 | 15.0 | G1/4 | 85 | - | - | G1/2 |

◇Note: Testing vacuum level -60kPa.Workpiece with smooth and clean surface. The data of pull-out force as above are figured out

without considering safety factor. The data may be different according to different workpiece surfaces.

| Spare parts | ||||||||||

| Item | Model | Applicable flat rectangular foam rubber pad | ||||||||

| NF | OF | |||||||||

| Sponge | SOP40NF | SOP40OF | SOP40 | |||||||

| SOP64NF | SOP64OF | SOP64 | ||||||||

| SOP92NF | SOP92OF | SOP92 | ||||||||

| SOP127NF | SOP127OF | SOP127 | ||||||||

| SOP180NF | SOP180OF | SOP180 | ||||||||

| SOP220NF | SOP220OF | SOP220 | ||||||||